Titanic Tours: Making Titanic Watertight

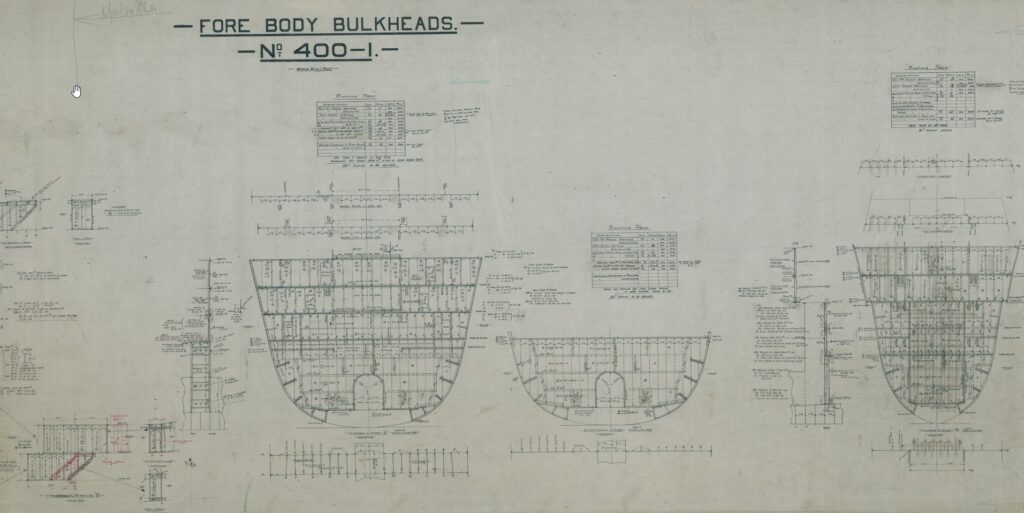

Titanic Tours: Making Titanic Watertight One of the much-ballyhooed features of the Olympic-class liners was their safety features. It would be these safety features, including her watertight doors and subdivision, that would cause the trade publication Shipbuilder, in their 1911 special number, to declare Olympic and Titanic “practically unsinkable.” Surviving a collision at sea was seldom a guarantee, but ships built before Titanic, in some cases many years before, had survived collisions with other ships and even with icebergs. Sinkings, however, were not uncommon in such incidents, with the RMS Republic in 1907 and the RMS Empress of Ireland in 1914 showing that collision damage much less widespread than on Titanic could cause a vessel to founder. Still, despite the accident to Titanic on her maiden voyage, and the later loss of her sister Britannic during World War I, the Olympic-class ships were designed and built with a high degree of safety features. Chief among these features was the cellular double bottom we’ve already discussed in Part 1 of this series. The double bottom formed an inner skin along the vulnerable bottom of the ship. If one of these ships ran over a submerged wreck or rock, it may puncture the outer skin, but would potentially leave the inner skin unscathed, allowing very minimal flooding to occur and permitting the ship to continue with her voyage. Titanic also had watertight bulkheads that divided the lower decks of the ship. Fifteen transverse bulkheads, running from one side to the other, created sixteen watertight compartments. The largest of these would be the space reserved for the ship’s enormous reciprocating engines. Others were of varying sizes, with the bulkheads also not proceeding in a straight vertical line. These bulkheads were lettered from the bow beginning with A and ending with P, omitting the letter I. Each bulkhead rose from the top of the double bottom (known as the Tank Top) as high as either the Upper Deck (E Deck) or the Saloon Deck (D Deck) and remained watertight to that height. The decks themselves were, for the most part, not watertight, lending to the more modern descriptions of the ship’s subdivision as similar to that of an ice cube tray. These bulkheads, pierced by watertight doors that we shall examine in a moment, gave the liners a high degree of survivability in a collision. One of the worst mishaps that could occur at sea was a collision with another vessel that opened two adjoining compartments to the sea. The Olympic-class ships could survive such a scenario. They could also survive an accident that damaged any three of the first five compartments or even the first four compartments from the bow. Unfortunately for Titanic, her damage just exceeded these possibilities, dooming her. A side-swipe collision opening five or six compartments was not a common or likely scenario, so it was believed that these new ships could survive virtually any mishap that would befall them. Most of these bulkheads (excluding E, F, G, H, and J) had watertight access doors built into their structure. When closed, the bulkhead was watertight. At the level of the Tank Top (the floor of the boiler rooms, coal bunkers, and engine spaces), these doors were of the vertical-sliding variety we are familiar with from films and photographs. These doors were more narrow aft of the boiler rooms, the wider doors in the boiler rooms allowing for the transportation of coal from the bunkers in wheelbarrows. The doors were each held open using an electronic clutch that could be released locally or remotely. If released, the doors would drop quickly into the closed position and thus seal the bulkhead. Each door also was equipped with a float system that would automatically close the door if water rose to 1 ½ to two feet above the tank top. Once closed, the only escape from that compartment would be up vertical escape ladders. These variously led to E Deck, where Scotland Road was located, or up to the Boat Deck. Above the boiler and engine spaces on E Deck and D Deck, the bulkheads were pierced by horizontal-sliding watertight doors. These had a similar look and construction, but operated on a rack and pinion system that would press the door firmly against the bulkhead once closed. These doors could be closed locally from either the same deck or from the deck above using hand cranks. Finally, the liners were equipped with several watertight doors on hinges, which operated the same as a standard door, with a rubber gasket around the rim. These could be sealed by pulling the door shut and turning several “dogs” to firmly seal the gasket to the frame. After the sinking, several design changes were made to both the building Britannic and, during her next overhaul, the Olympic. These would expand the two ships’ double skin from the bottom up the sides, extend some of the watertight bulkheads to B Deck, and provide a panel on the ship’s bridge that showed the status of the watertight doors. This panel is erroneously depicted as being aboard Titanic in most films, but it was not a part of her design. Other smaller changes would also be made, and together these would allow the Olympic and Britannic to survive a Titanic-style accident. Each vessel would now be able to float with her first six compartments opened to the sea. Unfortunately, despite these design changes, Britannic would succumb to a mine in 1916 while serving as a hospital ship. Next Week: Titanic’s Expansion Joints Written By: Nick DeWitt Previous Next A look at the bulkhead design from a bow-on perspective, showing the overall shape of the bulkheads and the ways in which various doors pierced them at each deck. Photo: Titanic Connections Archive Previous Next The starboard elevation plan used at the British Titanic Enquiry in the summer of 1912, showing each watertight bulkhead labeled below the hull. Photo: Titanic

Titanic Tours: The Framing of the Titanic

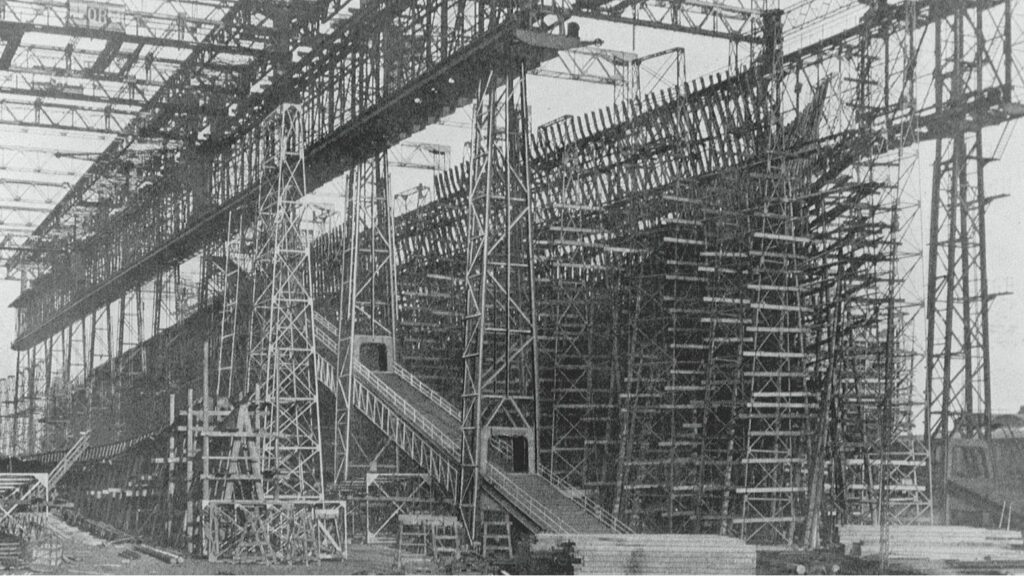

Titanic Tours: The Framing of the Titanic Last week, we looked at the visible outer part of the ship’s hull, her plating, castings, forgings, and rivets. We also discussed the way in which the individual plates were assembled. The plates, which formed Titanic’s outer skin, would not, however, have anything to attach to if not for the frames. The frames inside a ship’s hull are not visible in exterior photographs and are only somewhat evident in photographs of the interior. They are like the skeleton in a human body, giving a ship its overall shape and also providing strength and internal structure. Ships are divided by transverse frames spaced at intervals from the stem to the stern. While various numbering schemes for frames can be used, Titanic’s frames were numbered from amidships, with the exact middle frame left unnumbered. Each frame radiating from that was numbered sequentially and denoted as either forward (“F”) or aft (“A”) of the midship frame. Thus, the frame directly forward of amidships was “1F” and the one directly aft was “1A.” At the forward perpendicular, the forward-most frame was 156F. At the front of the sternpost was the aftmost frame, number 148A. The transverse frames were spaced differently in different areas, closer together at the bow (as close as 24 inches) and stern (as close as 27 inches) and further apart amidships (up to 36 inches). The closer spacing was due to the ship’s experiencing higher stresses on the hull at the ends. The frames ran from the tank top above the cellular double bottom (which formed their floor) to B deck, including the forecastle and poop decks. This formed the “box girder” of the ship’s hull, a hull form that proved incredibly strong and resistant to the high stresses of the North Atlantic routes. Each frame was composed initially of a straight steel bar that was then bent to the needed shape. The frames, once attached to the ship’s bottom, were joined by beams at each deck level. These were supported vertically by pillars and longitudinally by girders. Stringer plates were also fitted in specific areas to increase strength, with these running horizontally along the frames where the vertical distance between beams was larger (as in the holds, boiler rooms, and engine spaces). Stringers were also fitted at B-deck level for added strength. Framing of the ship would be completed before plating, as the plates would attach to the frames. Frames would subsequently be used to identify locations on the ship (you can often see a frame referenced in studies of the damage by the iceberg, for example). With the beams and pillars giving a ship the basics of its internal form, rooms and interior spaces could be constructed around them when the time came. Next Week: Making Titanic Watertight Written By: Nick DeWitt Photo Credit: Titanic Connections Archive Olympic’s framing is nearly complete in this image, showing the skeletal structure which gives the ship her overall form. This looks at her from her starboard bow, with the beginnings of Titanic just visible on the left of the frame. A close-up view of Titanic’s framing in progress

Titanic Tours: The Hull

Titanic Tours: The Hull This week, we’ve arrived at something that everyone will be able to recognize right away: Titanic’s steel hull. The construction of her hull is quite intricate, which becomes evident when one closely analyzes photographs of it. From the thousands of rivet heads to the rows of plating defined by their slight overlap, the hull is a study in the shipbuilding techniques of the early 1900s. Let’s start with the basic materials that made up the hull. Titanic’s hull was made up of individual plates, each of them averaging 30 feet in length and six feet in width, with a thickness averaging one inch, but thinning toward the bow and stern ends. The largest plates were 36 feet in length. Each plate weighed in around four tons. The plates were of mild steel, rolled in a low-speed mill, and were of extremely high quality for the time. The plates were held together by rivets, about three million of which were used in her overall construction. Shipbuilder magazine’s special number on Olympic and Titanic notes that over 500,000 of these rivets were located in the double bottom we discussed last week. The rivets were of wrought iron and of various sizes up to one and a quarter inches in diameter. The rivets along the sides of the hull, where the plates were relatively flat and the holes easy to access, were driven hydraulically. The ones at the ends and at the turns in the hull where hydraulic riveting wasn’t possible were driven by hand-hammering. The rivets were placed while still white hot, allowing them to expand into the hole as they cooled. Other parts of the hull, such as the propeller shafts and rudder post, were made by the process of forging, or hammering or pressing a heated steel into a required form. Likewise, the ship’s rudder, stem, and stern frame, among other components, were made by casting, where molten steel was poured into a cast, or pattern. Both casting and forging were used for special shapes that couldn’t be rolled in a mill as the plates were, and also to create parts that were required to be particularly strong and stand up to stress. Two methods were used to assemble the hull, giving its distinct pattern. The lower part of the hull was built with the “clinker” method, where each row, or strake, was placed outboard and overlapping with the previous and lower one. Once the turn of the ship’s bilge was passed and the hull proceeded upward to form the sides of the ship, the method switched to an “in-and-out” one, where an inner strake was positioned against the individual frames and alternated with an outer strake that overlapped the adjacent inner strakes. While much has been made of the strength (or lack thereof) of Titanic’s hull and rivets, it’s important to note that Titanic’s construction used the best methods and materials available at the time. As Harland and Wolff built ships for White Star on a cost-plus basis, there was also no incentive or need to cut corners to meet a budget. Finally, as Titanic sank, her hull was subjected to extraordinary stresses and not only stood up beyond her design specifications and the expectations of her builders, many of her rivets and hull plates remain fully in place today on the ocean floor. The hull was formed around a series of frames. Next week, we’ll take a look at how the framing was completed. Next Week: Titanic’s Frames Written By: Nick DeWitt A close-up of Titanic’s side, showing in great detail both visible riveting (on C and D deck) and the “in-and-out” method of overlapping the plates on the side of the hull The workshop at Harland & Wolff where castings were made. Here, you can see forms for some of the propeller blades, including a workman finishing a blade on the right.